UV coating creates a high gloss-like surface by applying a clear liquid to paper substrates. And curing it with ultraviolet radiation. A UV-coating machine completes the UV coating process after printing. UV packaging coating has the power to make your artwork designs come to life. Moreover, it gives your finished packaging design a more streamlined appearance.

Let’s start by discussing the UV process’s components and how you might use them in your bespoke packaging project.

UV Coating Activity

Ultra Violet coating is one of the most widely used finishing techniques for packaging.

The clear liquid compound includes the following components to ensure it firmly adheres to the packaging’s surface.

- Calcium

- Carbonate

- Kaolinite

- Polyethylene

We use a silkscreen or roller to apply the liquid compound to a surface in order to disperse the coating evenly. Then we use wet coating, cure under UV radiation, and dry entirely in a couple of seconds. We use layers frequently to safeguard the longevity of packing surfaces since they are water-resistant.

You can apply the UV-coating to all box surfaces or only certain ones.

What is Spot UV?

The same liquid substance that would be in UV-coating will be in spot UV printing. Moreover, the sole distinction is that the coating is now exclusively in specific places rather than liberally covering the packaging’s surface. However, this may consist of logos, text, or pictures. Spot UV draws attention to critical components, giving packaging designs greater depth.

What Are the Common Uses of UV Coating?

UV coatings are a flexible method we can use on paper products.

However, it functions best with heavier, thicker papers like corrugated packing and rigid set-up boxes.

UV coatings are fantastic in enhancing and truly bringing to life artistic creations.

As a result, luxury packaging will almost certainly use this finish to give it an extra sense of high quality.

The e-commerce sector has also been adopting this coating technology more frequently to increase the tensile strength of their shipping packaging.

Types of Uv-Coating

You can consider the following options depending on the look and feel. Moreover, what do you want your UV-coated printed boxes to convey:

Gloss UV

As the name suggests, the glossiest of all coatings is gloss UV. Sheen/Matte UV is attractive if you want a brilliant sheen and a lovely patina. You should save gloss UV coatings for spot UV printing to prevent producing extremely reflective (and therefore less readable) surfaces and an excessive shine.

V matte

A matte finish exudes a sense of grandeur and refinement. You can also apply matte spot UV to places you want to accentuate. As an alternative, you can choose flood protection UV, which completely encases the sheet and creates a vibrant, rich effect.

UV pearlescent

This kind of coating produces a beautiful iridescent shine. It blends metal dots in various colors with gloss UV treatments to get this effect. It emits an iridescent sheen that we frequently use in cosmetics packaging.

UV Orange Peel

Orange peel UV produces a distinctive tactile feel, adding visual appeal thanks to its raised shape and textured finish.

The textured coating provides a tactile element to your package. However, it makes it interesting to handle in addition to being eye-catching.

Advantages and Disadvantages

UV coating is a popular finishing process in printing and packaging. It involves applying a clear liquid coating to printed materials and curing it under UV light. Here are some of the advantages and disadvantages of UV coating:

Advantages:

- Enhanced Durability: UV-coating creates a hard, scratch-resistant surface that provides more protection against damage than traditional coatings. It also helps to prevent fading from prolonged exposure to sunlight and other environmental factors.

- Improved Appearance: UV-coating can enhance the appearance of printed materials by creating a glossy, high-quality finish that makes colors pop and images stand out. It can also add texture to printed surfaces, giving them a tactile feel.

- Quick Drying Time: UV-coating cures instantly under UV light, so no drying time is required. It allows for faster production times and reduces the risk of smudging or damage during handling.

- Eco-Friendly: UV-coating is considered more environmentally friendly than traditional coatings, as it does not contain solvents or emit volatile organic compounds (VOCs).

Disadvantages:

- Cost: Ultra Violet coating is more expensive than traditional coatings due to the specialized equipment required and the higher cost of the layer itself.

- Difficulty in Recycling: Because UV-coated materials are more complex to recycle than non-coated materials, there may be challenges in finding a recycling center that accepts them.

- Limited Applicability: UV box coating cannot be on all types of materials, such as those that are heat-sensitive or have an uneven surface.

- Increased Risk of Smudging: While UV box coating dries quickly, there is a risk of smudging or damage during handling if the layer is not entirely ok.

In summary, while coating has many advantages, such as durability, enhanced appearance, and quick drying time, it also has disadvantages, such as cost, limited applicability, and increased risk of smudging. It is essential to consider these factors when deciding whether to use UV Box coating for your printing or packaging needs.

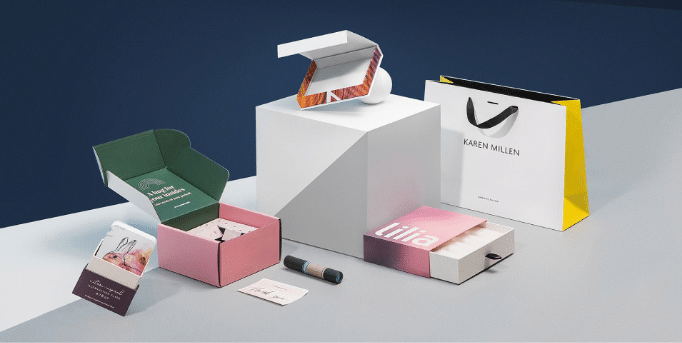

Why Choose Us?

We also understand the importance of meeting deadlines and delivering products on time, which is why we have a highly efficient production process that allows us to complete projects quickly without compromising on quality. Our designers and packaging experts work closely with clients to ensure that their packaging meets specifications and is tailored to their unique brand image.

Ultimately, we aim to provide exceptional customer service and support throughout the entire UV coating packaging process, from concept to delivery. We are here to build long-term relationships with our clients and help them achieve their business objectives through effective packaging solutions. Choose us as your custom packaging company and experience the difference in quality, service, and value.